New Way Air Bearings ® and our Externally Pressurized Porous (EPP) Gas Bearings have been heavily integrated in the turbomachinery sector for many years, both on the research side as well as commercial integration and manufacturing. At the 7th European Conference for Energy Systems, Logan Rapp of Sandia National Labs presented a paper on Supercritical Carbon Dioxide Externally Pressurized Porous Media Air Bearings; on which our founder and CEO Drew Devitt was a contributing author.

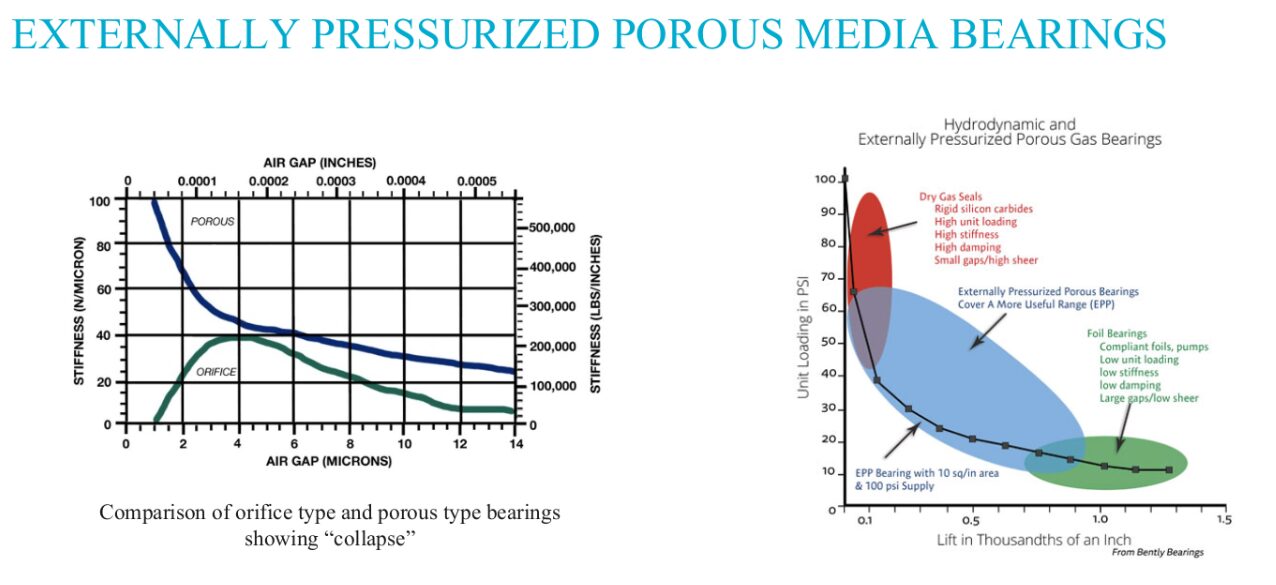

Unlike aerodynamic bearings which have a high unit loading and low lift height, producing a highly stiff and highly damped system at the expense of high shear, and foil bearings which are minimally damped but have low shear, EPP bearings sit in a useful middle zone, providing high stiffness and damping while also maintaining near zero power loss from fluid shear. Thanks to the torturous pathways of the porous media bearing surface, New Way bearing products exhibit a positive relationship between stiffness and damping, allowing you to design systems which do not require a tradeoff between two critical parameters.

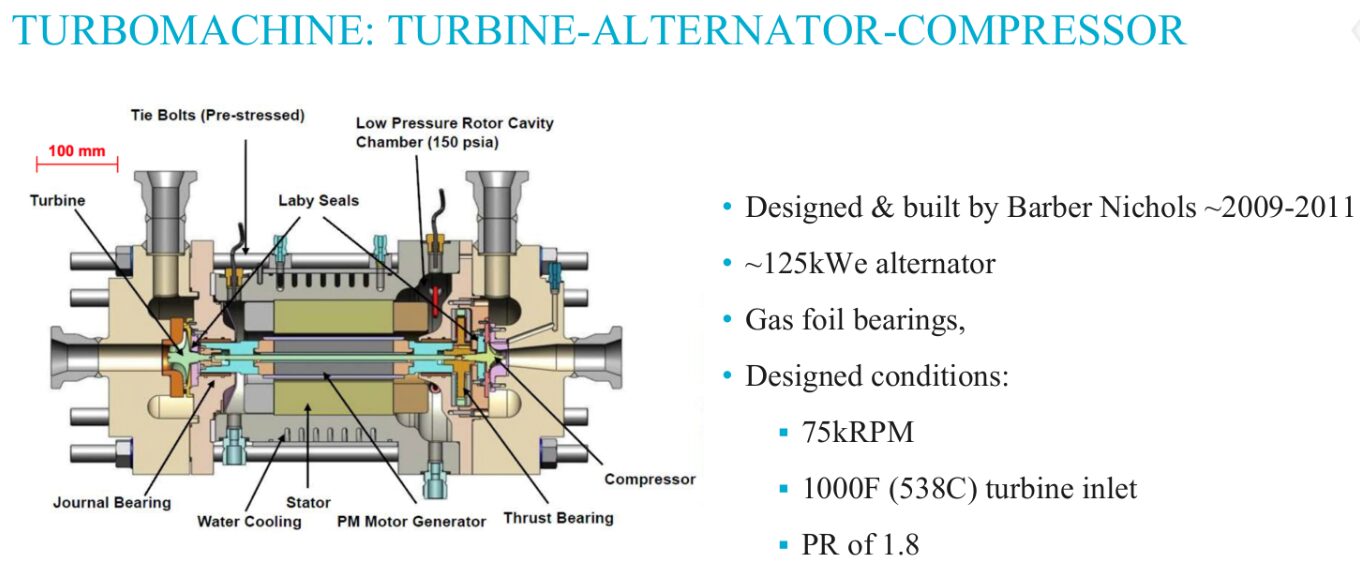

Sandia National Laboratories has a robust experimental facility for supercritical CO2 research, allowing for testing heat exchange, pressure fatigue, individual bearing and seal testing, as well as a complete turbomachinery system. For testing externally pressurized porous media technology, a turbine-alternator-compressor (TAC) was used, originally supported on gas foil bearings, spinning at 75k ROM, with a 1,000F turbine inlet.

It is noted that while foil gas bearings are a solution for small scale sC02 systems, their failure rate and inability to scale have led to the search for alternative solutions, and the evaluation of technologies like New Way porous media. In prior testing programs, a tilting pad porous bearing design was installed to support a 700lb rotor, which was evaluated for resiliency against shear loading, fluid ingress and dynamic loading.

Porous media bearing pads underwent a battery of tests in the Sandia facilities, including an acceptance test to measure mass flow as a function of pressure, axial load testing, radial load testing and thermal stability testing. During acceleration and rampup between varying speeds, no vibrations or instabilities were observed in the porous media based bearing system. Leakage flow rates on the order of 10g/s to 25g/s were observed, and were shown to be a function of absolute pressure and temperature, with insensitivity to pressure differential at steady state operations.

Once experimental, our turbomachinery bearings can now be purchased as off the shelf products, with bespoke engineering services available to develop turnkey products and integrate into unique assemblies. If you want to know more about our turbomachinery research or have a product question, please contact us!