New Way Air Bearings ® and our Externally Pressurized Porous (EPP) Gas Bearings have been heavily integrated in the turbomachinery sector for many years, both on the research side as well as commercial integration and manufacturing. At the American Society of Precision Engineering’s 2019 technical expo, our founder and CEO Drew Devitt presented his current research on the usage of New Way bearings for turbomachinery applications, combining the benefits of oil and foil bearings with unique benefits like 900psi load capacity and operational conditions up to 600C.

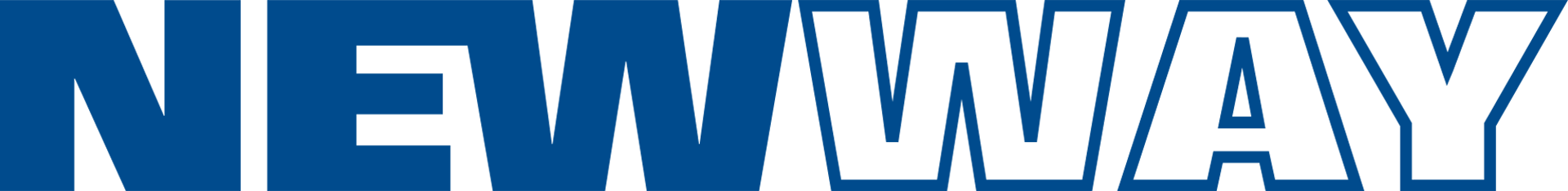

Unlike aerodynamic bearings which have a high unit loading and low lift height, producing a highly stiff and highly damped system at the expense of high shear, and foil bearings which are minimally damped but have low shear, EPP bearings sit in a useful middle zone, providing high stiffness and damping while also maintaining near zero power loss from fluid shear. As we can see in the below image, traditional oil based bearings can incur a power loss on the order of 30,000W for a 0.005 oil gap, whereas a comparable porous media bearing with air as its fluid medium only experiences in the range of 1,000W power loss at most. Additionally the power loss is nearly invariant with air gap height.

A Dresser Rand Test Rotor was mounted on New Way gas bearings at TurboCare in Houston, Texas, where we conducted a rigorous testing regime for shear loading, environmental conditions and dynamic loading. This rotor is 700lb, 2 meters long and with 100mm journals, designed specifically to replace a 10 stage compressor rotor. The 5 pad tilting design was developed to mimic existing oil bearing designs, however the New Way system can run on both CO2 and nitrogen. Environmental condition modelling consisted of spraying 3 fluid ounces of water directly between two pad bearings, through which the shaft continued at speed with no identifiable effects on bearing performance. For dynamic load testing, the bearing and rotor system was loaded at 200lb, 400lb and 800lb, with the 400lb unbalanced, synchronous load applied for a continuous 6 hour run time.

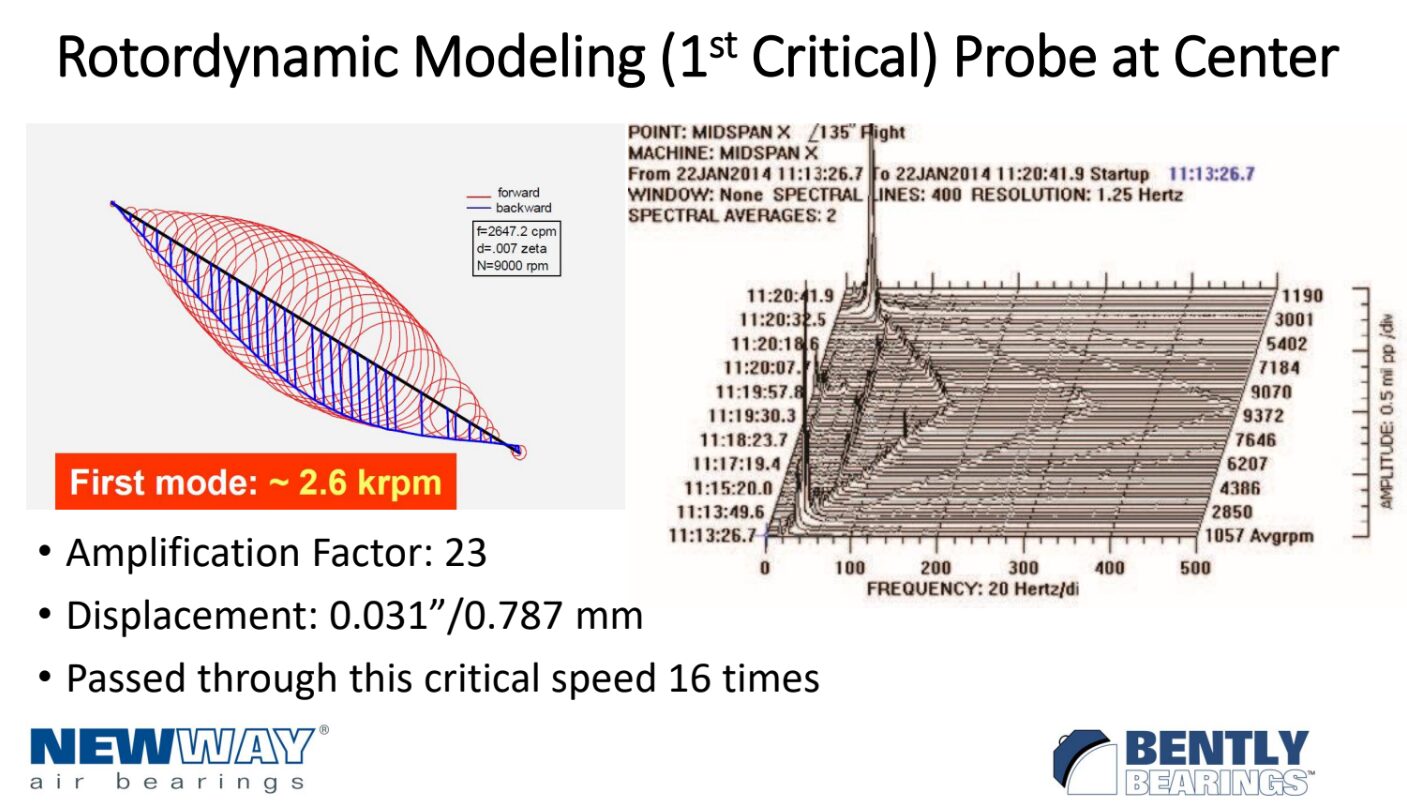

After environmental and dynamic load testing, the frequency spectrum of the bearing was analyzed. It is well understood that porous media air bearings, through the squeeze film effect, produce a positive relationship between stiffness and damping, which acts to virtually remove resonant behavior from dynamic systems. In this system, there is only one meaningful critical speed around 1,100 RPM, but the system only registers a displacement of 0.031” at its peak. The test rotor was also spun up to pass through this critical speed 16 times, demonstrating reliability and a proven capability to damp resonant behavior. Attempts to extract a second critical mode were ultimately unsuccessful, due to the highly stiff nature of the porous media system, which only allowed 0.003” of motion at its peak.

Once experimental, our turbomachinery bearings can now be purchased as off the shelf products, with bespoke engineering services available to develop turnkey products and integrate into unique assemblies. If you want to know more about our turbomachinery research or have a product question, please contact us!