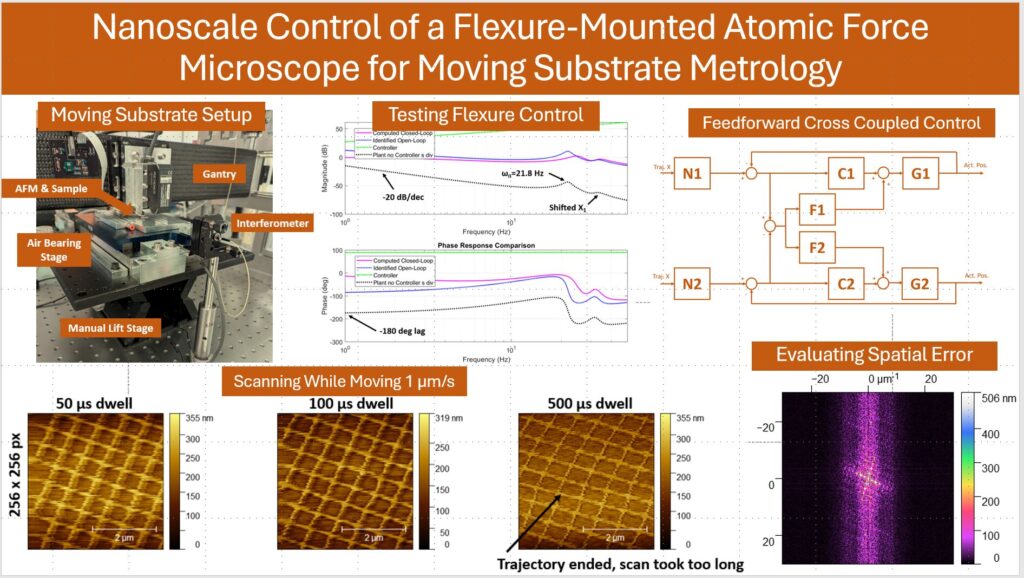

Porous media air bearings continue to offer their remarkable benefits to academic research and scientific progress, as we cover the work of Barbara Groh and her collaborators at the Walker Department of Engineering at the University of Texas at Austin. In collaboration with the Microsystems and Nanotechnology Division at the National Institute of Standards and Technology (NIST), Dr. Groh and others have investigated moving substrate metrology for atomic force microscopy, all built on a micro electromechanical system (MEMS) using New Way’s own linear slides.

Atomic Force Microscopy (AFM) is an invaluable tool for the characterization of nanoscale features, but it is typically limited to static substrates and has substantial imagining times. Moving environments are typically subject to high noise, and thus limits the practical use of AFM. Dr. Groh and her colleagues have developed their MEMS based AFM system for the purpose of disturbance rejection, following a moving substrate while maintaining a static imaging position. This opens the door to using AFM as an in situ inspection technology in manufacturing processes, on a much smaller scale but similar to how New Way Air Turns allow for no contact inspection of roll to roll processes.

The New Way linear stage for this research was provided free of charge, by way of our continued involvement and support of the American Society of Precision Engineering (ASPE) student challenge, which we sponsor every year. Thanks to the hysteresis free motion of porous media linear stages, Dr. Groh was able to successfully conduct AFM linear scans of a 4 micron x 4 micron square in under 5 seconds.

In the below introductory slide for Dr. Groh’s presentation at the ASPE topical meeting, we can see the integration of the New Way linear slide with actuated gantry configuration, and the remarkably smooth frequency response this system produces.

Dr. Groh has since graduated from her PhD program, but remains a collaborator with New Way Air Bearings as a workforce development coordinator in the Semiconductor Science and Engineering Department, developing practical coursework and lab experience for students with feedback from industry partners like ourselves.

Linear slides like the one employed in this research are available in four different configurations, covering low profile, continuously supported, end supported and fully integrated configurations, and all of these products can be developed on a bespoke basis to meet the needs of your particular application.

To learn more about New Way products or our collaboration with Dr. Groh and the American Society of Precision Engineering, please contact us.