Products

- Spherical Air Bearings Standard Line

- Hubspot Form IDFlat Rectangular Air Bearings

- Components

- Air Bars

- Air Bushings

- Air Spindles

- Bonded Bearings

- 12mm Nominal Width Bonded Bearings

- 15mm Nominal Width Bonded Bearings

- 18mm Nominal Width Bonded Bearings

- 23mm Nominal Width Bonded Bearings

- 38mm Nominal Width Bonded Bearings

- 48mm Nominal Width Bonded Bearings

- 72mm Nominal Width Bonded Bearings

- 97mm Nominal Width Bonded Bearings

- 122mm Nominal Width Bonded Bearings

- 147mm Nominal Width Bonded Bearings

- Flat Rectangular Air Bearings

- Flat Round Air Bearings

- Linear Slides

- Radial Air Bearings

- Retrofit Bearings

- Spherical Air Bearings

- Thrust Bushings

- Vacuum Preloaded Air Bearings

- CMM Bearings

- Mounting Components

- New Technologies

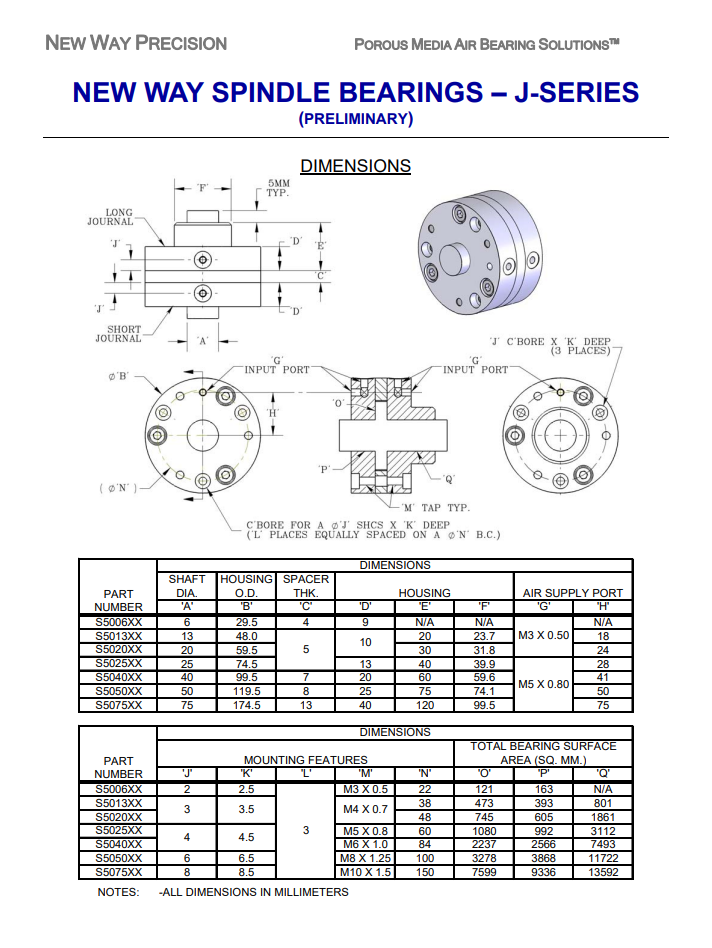

J Series Air Spindles

New Way® Air Spindles provide a frictionless alternative to magnetic, oil, or bearing-based spindle solutions. Through the use of our Porous Media Technology™, we generate a micro-thin cushion of air between the rotor and the stator, eliminating sub-synchronous motion and reducing asynchronous error by orders of magnitude.

-

Lower synchronous error: The rotor’s single-piece construction allows for nearly perfect geometry, significantly reducing fundamental synchronous error (the deviation from a perfect rotational position per revolution).

-

Improved accuracy for precision applications: Ideal for tasks like optical inspection or other applications where slower speeds and high positional accuracy are critical.

-

Manufacturing quality: The monolithic rotor design reduces the need for complex grinding and alignment processes, ensuring more consistent error motion performance compared to multi-piece spindles.

Other key benefits applicable to all porous media air spindles include:

Unlike complex magnetic suspension or oil-based lubrication systems, the air spindle’s Frictionless Motion®️ means zero dynamic, contacting components, eliminating mechanical wear, and increasing the lifespan of your assemblies. With friction eliminated, air spindles open the door to far faster rotational speeds, providing faster motion while retaining a degree of accuracy only limited by the servo and controller system you choose.

New Way Air Spindles are an exceptionally low flow technology, taking almost six hours to push one cubic meter of air through a 50mm x 100mm bearing, and thus, are extremely efficient in operation when compared to orifice-based systems. If airflow is somehow disrupted to the air bearing, the porous nature of the bearing surface means depressurization will occur slowly, allowing for a soft landing, ensuring the spindle and the guide surface remain undamaged. Contrast this with orifice and magnetic bearings which can often fail in catastrophic ways, and we see how air spindles provide all the benefits with none of the drawbacks.

Click to view full testing and analysis report. The unique nature of our porous media products makes air spindles an inherently cleanroom compatible technology. While air is already cleaned and filtered prior to entering the bearing, the size of the openings in the bearing face acts as a natural sib-micron filter. Internal testing by New Way places all of our bearing products as being ISO Class 3 cleanroom compliant (less than 1,000 x 0.1μm particles / m3), and arguably even meeting the stringent requirements for ISO Class 1.

For the modern manufacturing facility, whether it be pharmaceutical, semiconductors, or aerospace, cleanroom manufacturing is rapidly becoming a best practice, and air spindles are up to the task.

All air spindles come in a variety of sizes and stator configurations to accommodate an array of rotary applications. Air spindles can be paired with a motor/encoder of your choice. Or, if you desire a fully integrated solution, New Way also offers Servo-Drive Rotary Stages, capable of 1.1-arcsecond precision.

New Way also has a proud history of providing bespoke engineering solutions, so if you need something made to your exact specifications, we have the in-house design and manufacturing expertise to make that happen.

- No asynchronous error motion

- Low synchronous error motion

- High-precision

- Faster rotation speeds

- Crash-resistant

- High stiffness

Applications

Don’t see your application listed? Tell us more about your precision rotary needs so we can find the right air-bearing solution for you.

- With only one rotating element, error motions are significantly reduced allowing nano-levels of precision.

- Without contact between the rotor and stator, mechanical issues common to rotary tables are virtually eliminated.

- Frictionless, non-contacting motion eliminates the need for food-grade lubricants.

- Ideal for cleanroom environments where outgassing can be a concern.

- High-speed rotation is a must for the precision lathes used to grind optical components.

- Nanometer levels of precision and 1.1-arcsecond precision afforded by a servo-driven rotary stage, providing the exact motion you need.

- Metrology

- Dynamometry

- Robotic-end effectors

- Drilling, boring, milling

- Ability to be paired with linear slides for multi-axis motion

J Series Spindle Product Line

J Series Air spindles are available in a wide range of standard sizes, in both round and square stator configurations, for your specific application. Don’t see your size here? Contact us to discuss custom options.

Comparision Table

| Size | SKU | Part # | Input Pressure | Axial Load | Radial Load |

|---|---|---|---|---|---|

| 2.95 in75 mm | S5075XXSS-375 | S5075XXSS-375 | 60 psi0.41 MPa | 353 lbs1572N | 01 = 14.6lbs , 02 = 30lbs, 03 = 22lbs01 = 65N, 02 = 133N, 03 = 99N |

| 2 in50 mm | S5050XXSS5050XX | S5050XXSS5050XX | 60 psi0.41 MPa | 152 lbs98N | 01 = 14.6lbs , 02 = 30lbs, 03 = 22lbs01 = 65N, 02 = 133N, 03 = 99N |

| 1.57 in40 mm | S5040XXSS5040XX | S5040XXSS5040XX | 60 psi0.41 MPa | 126 lbs463N | 01 = 14.6lbs , 02 = 30lbs, 03 = 22lbs01 = 65N, 02 = 133N, 03 = 99N |

| 1 in25 mm | S5025XXSS5025XX | S5025XXSS5025XX | 60 psi0.41 MPa | 50 lbs223N | 01 = 14.6lbs , 02 = 30lbs, 03 = 22lbs01 = 65N, 02 = 133N, 03 = 99N |

| 0.78 in20 mm | S5020XXSS5020XX | S5020XXSS5020XX | 60 psi0.41 MPa | 34 lbs154N | 01 = 14.6lbs , 02 = 30lbs, 03 = 22lbs01 = 65N, 02 = 133N, 03 = 99N |

| 0.5 in13 mm | S5013XXS5013XX | S5013XXS5013XX | 60 psi0.41 MPa | 22 lbs98N | 01 = 14.6lbs , 02 = 30lbs, 03 = 22lbs01 = 65N, 02 = 133N, 03 = 99N |

| 0.24 in6 mm | S5006XXS5006XX | S5006XXS5006XX | 60 psi0.41 MPa | 5.62 lbs25N | 01 = 14.6lbs , 02 = 30lbs, 03 = 22lbs01 = 65N, 02 = 133N, 03 = 99N |

CUSTOMER PROVEN SOLUTIONS

Questions

Contact us for a complimentary consultation and learn more about our radial air bearings!

Related Products

Learn More About the Porous Media Difference