Porous media based motion systems from New Way Air Bearings ® are renowned for their longevity, accuracy and repeatable precision, and today we want to highlight a newer application of our products: capacitive measuring systems. Capacitive measuring systems are an invaluable tool for the metrology industry, and any manufacturers and OEMs who work on parts with sub nanometer precision. As long as the part is conductive, capacitive measuring can be applied, meaning this tool is applicable to manufacturers in varied industries as semiconductor production, aerospace and satellite development, calibration systems and many many more.

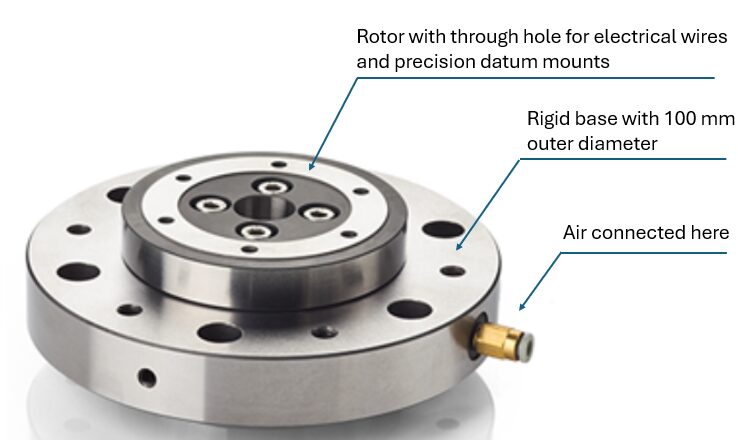

Recently our founder and CEO, Drew Devitt, was in attendance at the European Society for Precision Engineering (Euspen)’s 25th International Conference and Exhibition, held in Zaragoza, Spain. At the booth for our longtime partner and integrator IBS Precision Engineering, he walked visitors through a tabletop demonstration of the power of porous media, in this case an SS-55 “T” series Air Spindle for capacitance measurement techniques.

Because there is only one rotating element, as well as the fact that fluidic sliding interfaces induce a positively stabilizing squeeze film effect, porous media based rotary stages substantially reduce error motions, typically by an order of magnitude. As we can see in Drew’s video, the capacitance probe measures the gauge sphere with an asynchronous error on the order of 60 nanometers, with a synchronous error motion of 5 microns.

Our partners at IBS have a wealth of case studies on their integration of our rotary stages into capacitance measuring systems, including for rotational stage calibration like we saw in Drew’s video, as well as scanning electron microscope (SEM) stage focusing, spindle error detection and several other equally high precision, ultralow tolerance applications.

Porous media bearings themselves have formed the basis for ultra precise motion stages before. In fact we already sell a completely integrated servo driven rotary stage, which pairs a spotless brushless motion with a high resolution encoder to enable 1.1 arcsecond rotary resolution; accurate enough to position the world’s most productive stellar observatories, as well as underpinning custom built goniometer stages for integrators like IST Precision.

Our air spindles are available in a wide array of sizes, from the 55mm diameter SS-55 air spindle up to the 375mm SS-375 model, and every product you see on our website can be manufactured to spec as a turnkey product for your application.

Contact Us

Do you want to learn more about our experience with capacitance measuring systems, get an understanding for whether our technology is right for you, or speak with our engineering sales team for a quote. Contact us directly and our team will get back to you shortly!